Water cycle

Water treatment techniques

In the field of water treatment, the focus is on ensuring quality and safety.

Mastering the various water treatment techniques is essential to meet the specific needs of each customer.

Once the water has been treated and used by our customers, we offer natural, industrial and/or innovative technical solutions for treating wastewater.

Kamp Alliance is thus able to treat 95% of terrestrial fresh water, ensuring access to a clean and safe water source for our customers and the natural environment.

Our various water purification solutions

water purification solutions

Physico-chemical treatment

Coagulation-flocculation is a physico-chemical water purification process used for drinking water treatment or wastewater treatment. It is based on the principle that certain particles have difficulty settling naturally and are therefore treated chemically to induce settling.

Water produced by coagulation-flocculation

Coagulation-flocculation is a two-step process that overcomes this lack of sedimentation and eliminates unwanted particles through forced sedimentation and filtration.

Water produced by coagulation-flocculation

Coagulation-flocculation is a two-step process that overcomes this lack of sedimentation and eliminates unwanted particles through forced sedimentation and filtration.

Ultrafiltration

Ultrafiltration (UF) is a membrane separation method that distinguishes itself by the size of the suspended particles stopped, which is between 1 and 100 nanometres.

This size is too small for bacteria, yeasts and most viruses. In practice, ultrafiltration is mainly used to separate dissolved materials.

The operating pressure varies depending on the quality of the water to be treated, ranging from 1 to 10 bar.

The overall efficiency can reach 85%.

This size is too small for bacteria, yeasts and most viruses. In practice, ultrafiltration is mainly used to separate dissolved materials.

The operating pressure varies depending on the quality of the water to be treated, ranging from 1 to 10 bar.

The overall efficiency can reach 85%.

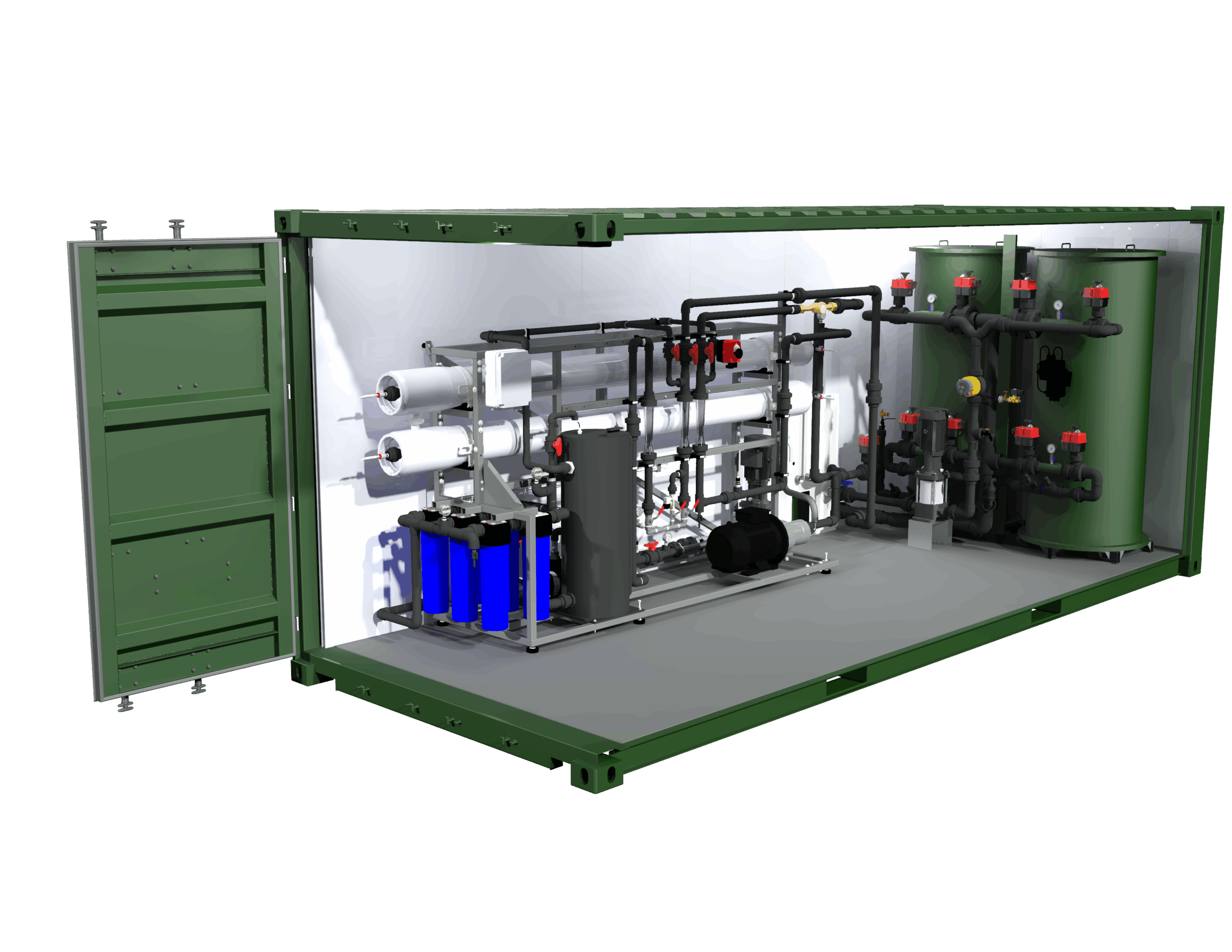

Reverse Osmosis

Reverse osmosis is a process for purifying water containing dissolved substances using a very fine filtration system that only allows water molecules to pass through.

This highly effective, very fine mesh often requires pre-treatment upstream to prevent clogging of the osmosis membranes. Pre-treatment can take the form of one or more processes in series, such as physical-chemical treatment, sand filtration, resin filtration, or ultrafiltration.

The operating pressure varies depending on the quality of the water being treated, ranging from 10 to 40 bar.

The efficiency is around 65%.

This highly effective, very fine mesh often requires pre-treatment upstream to prevent clogging of the osmosis membranes. Pre-treatment can take the form of one or more processes in series, such as physical-chemical treatment, sand filtration, resin filtration, or ultrafiltration.

The operating pressure varies depending on the quality of the water being treated, ranging from 10 to 40 bar.

The efficiency is around 65%.

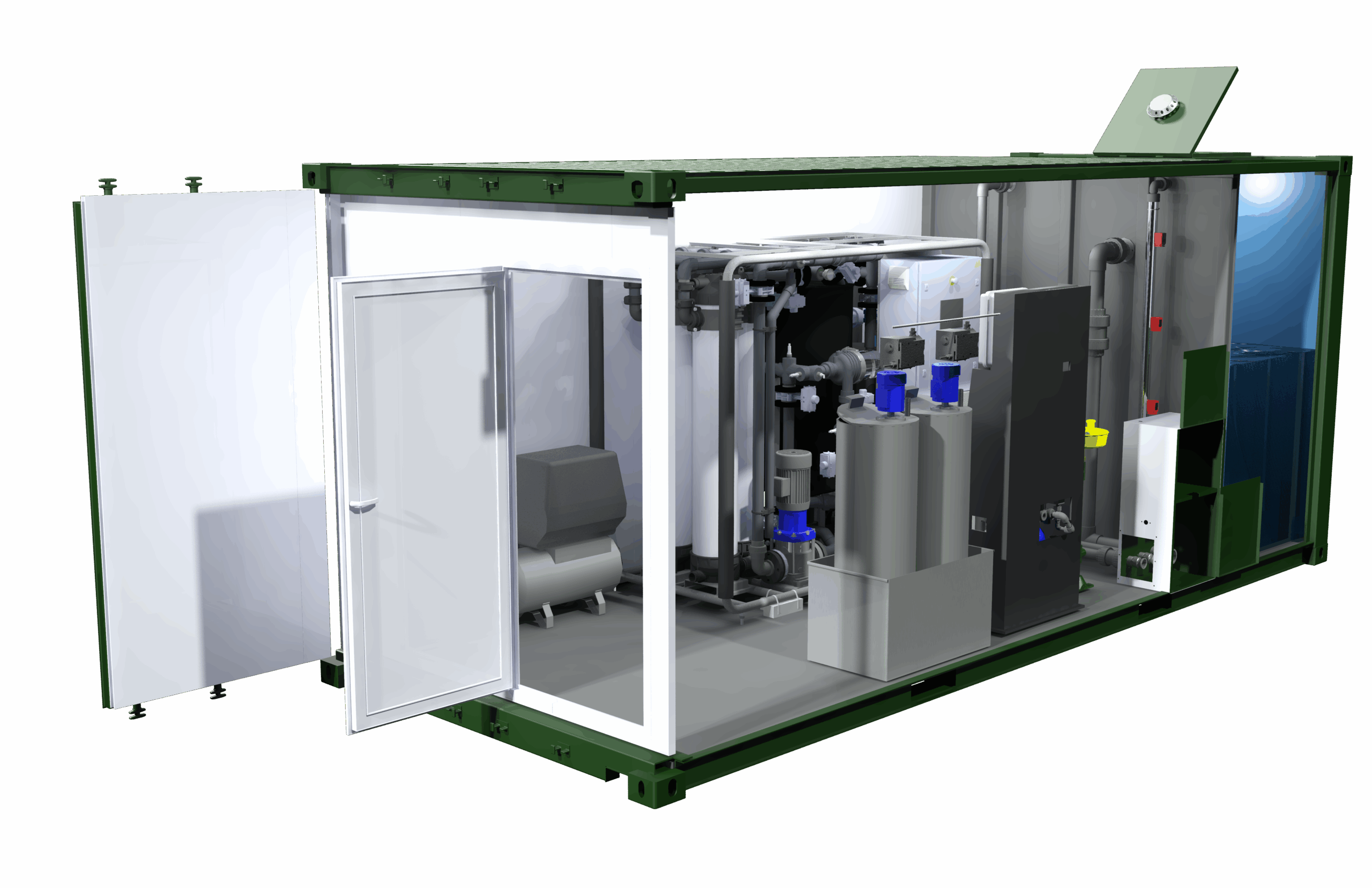

Chlorination solution

On-site chlorine production by electrolysis has the advantage of providing autonomy with good quality chlorine and avoids the need to transport chemicals.

Our othersolutions

Our other

Waste recovery

Multi-technical solutions

Design offices and field experts